Composition and Types of Cutting and Grinding Discs

March 25, 2020

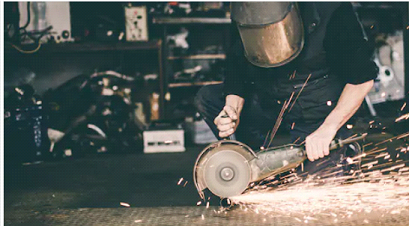

Orkon cutting wheels have both types. There are different types of resinoid-bonded abrasive cutting wheels that are flat, and another type which are raised hub – known as depressed center wheel. Flat type wheels generally are used for straight-on cutting on electric or pneumatic right-angle grinders or die grinders and chop saws, among other tools. Depreseed center wheels are required when there is some type of interference and the wheel needs to be raised up from the base of the grinder as it is in general power tools, but personal preference also plays a role in the decision. They are most commonly used with electric or pneumatic right-angle grinders.

Resinoid-bonded abrasive cutting wheels or cutting discs are available in various sizes and thicknesses. The most popular range is 2 to 16 inches in diameter, and common thicknesses are from 0.045 in. to 1⁄8 in. Thinner wheels remove less material during the cut but they finish the job faster. Some types of Orkon wheels cut faster than others. The abrasive raw material used in the wheel is one influencer on cut rate and consumable life. Metal Cutting Wheels come in several grain options, such as aluminum oxide, silicon carbide, zirconia alumina, ceramic alumina, and combinations of these materials.

While not as sharp as other grains, aluminum oxide provides toughness and good performance for cutting on steel. Silicon carbide, on the other hand, is a very sharp grain but not quite as tough, making it suitable for cutting nonferrous metals. Zirconia alumina is a self-sharpening, tough, durable grain that holds up well in a range of demanding applications. Ceramic alumina also is designed to self-sharpen as it “breaks” at predetermined points to maintain a consistent cut rate and long life.

While selecting an abrasive wheel, consider that products made with a mixture of zirconia or ceramic alumina with a harder bond typically cost more but offer durability and longer consumable life.

Users and buyers are requested to refer to the Orkon product manufacturer’s recommendations, product descriptions, and RPM ratings to select the proper wheel size and bonded abrasive material for your application. Matching the size and RPM rating of the tool to the size and RPM rating of the wheel is critical for safe and effective usage. Choosing the tool with the greatest amperage or amount of torque while staying within size and RPM requirements of the wheel will increase performance. Note that wheel have a shelf life, so make sure what comes in first goes out first (FIFO).